To verify the graphics quality and color fidelity of every order that leaves our facility, we have quality assurance measures in place such as:

State-of-the-art vision systems to catch even the smallest print defects

Density and spectrophotometers to numerically match printed colors to your proof

We’re able to deliver print runs that exactly match your specifications because of the legwork we do during prepress and the expertise we bring to the press.

To get printed flexible packaging that meets the strictest quality standards, reach out to our team today.

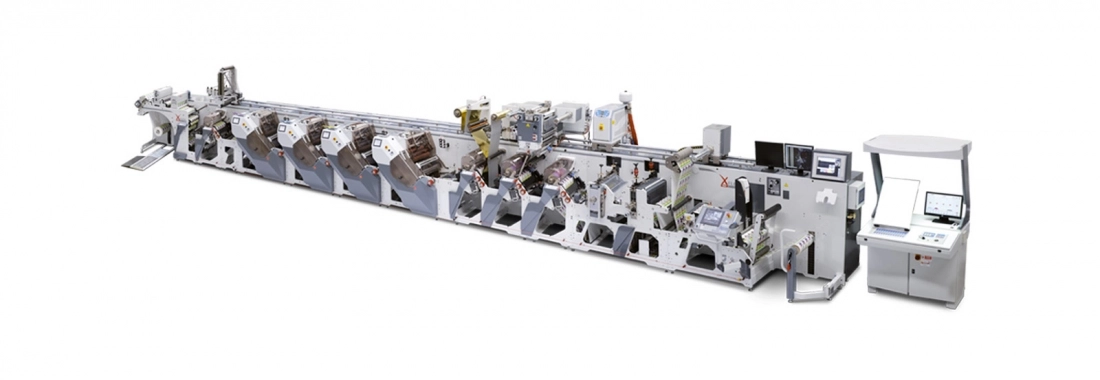

MODERN PRINTING MACHINES

GIVE US NEW POSSIBILITIES

OFFSET PRINTING

Offset printing is generally able to provide a higher quality print with finer details and richer colors. It is more suitable for high resolution prints and more complex graphic elements. Offset print has lower start-up cost since the printing plates are easier to make and it can therefore be more used for printing in lower quantities. In this area, the trend is towards increasingly sophisticated and state-of-the-art motifs. The production of printing plates typically involves water or digital processing, eliminating the need for environmentally harmful chemicals.

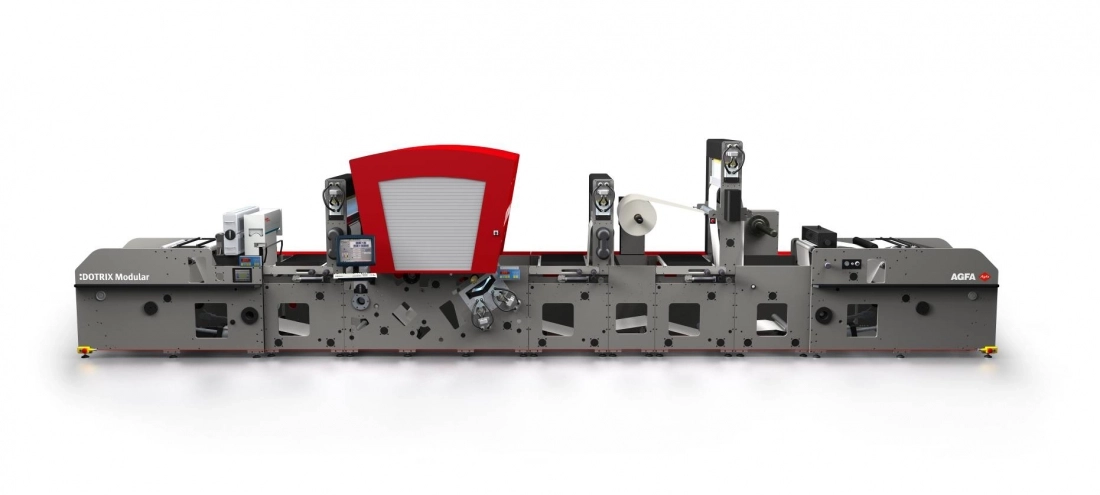

DIGITAL PRINTING

Digital printing excels in personalised, variable data, and marketing applications, making it a preferred choice in those areas. Cost-effective production thanks to digital prepress, which drastically reduces prepress time. No need for printing plates (except in the case of partial white printing) or plates. The process generates minimal waste, emits few emissions, and avoids the use of printing plates and harmful chemicals.

SPECIAL EFFECTS PACKAGING

Partial matt coating is the most common surface treatment applied to flexible packaging. It is a very refined design element which, compared to other effects, enhances delicate subtle motifs and typography. Recommendation. Lacquered areas will stand out visually and tactilely if only about 5 to 15% of the printed area is lacquered.

Matt and gloss effects are also easily achieved with a digital machine. Further interesting effects can be achieved by clever combinations of laminate, ink and colour coverage. As an example, quasi-metallic effects can be created.

FLEXO printing

Flexo printing is ideal for prints with simpler graphics and less detail. It provides fast and efficient printing with good coverage and colors. The start-up cost are higher flexo printing than offset printing. All printed substrates can be single layer, but can also be part of multiple layers. In order to meet the requirements of our clients, we guarantee individual technological solutions, the highest quality of packaging and its safety for contact with food.

The choice between flexo and offset printing or digital printing is not about choosing the better method. Rather, it's about choosing what best suits your specific printing needs. So pull out your list of printing needs and contact us - your perfect printing partner awaits!

IN-HOUSE PREPRESS PREPARATION FOR ABSOLUTE CONTROL OF PRINT QUALITY AND DELIVERY DATES

Our prepress team consists of 2 employees with different roles and responsibilities. Their main goal is the successful implementation of customer requirements throughout the entire prepress phase. This includes factors such as design, technical drawing, ink selection and other parameters that affect the perfect outcome of the job. The data you create is professionally processed with the appropriate software. Thanks to our years of know-how, we can offer you perfect prepress services.

- If you have any further questions, please contact our prepress team.

- For instructions on how to deliver print data correctly, please click here.